The combustion of fossil fuels for the production of energy currently produces over 35 gigatons of CO2 per year, which cannot be accommodated in the natural carbon cycle. This, in turn, has led to an unprecedented increase in the concentration of CO2 in the atmosphere over the last two centuries. Considering that our modern economies still rely heavily on fossil fuels for energy production, it is extremely urgent to develop technologies that minimise CO2 accumulation in the atmospheric environment.

A highly attractive solution for mitigating the impacts of CO2 emissions in the atmosphere is to harness renewable electricity by turning unwanted CO2 into valuable fuels and feedstocks. Doing so not only turns a polluting waste product into something useful, but also reduces our reliance on fossil fuels that causes the problem in the first place. To convert CO2 into a fuel, however, we need appropriate and highly effective catalysts that can overcome the energy barrier of the respective reactions and accelerate them. A catalyst, therefore, needs to be highly selective and efficient for the specific reactions, as well as durable enough to guarantee a long operating lifetime.

Project objectives

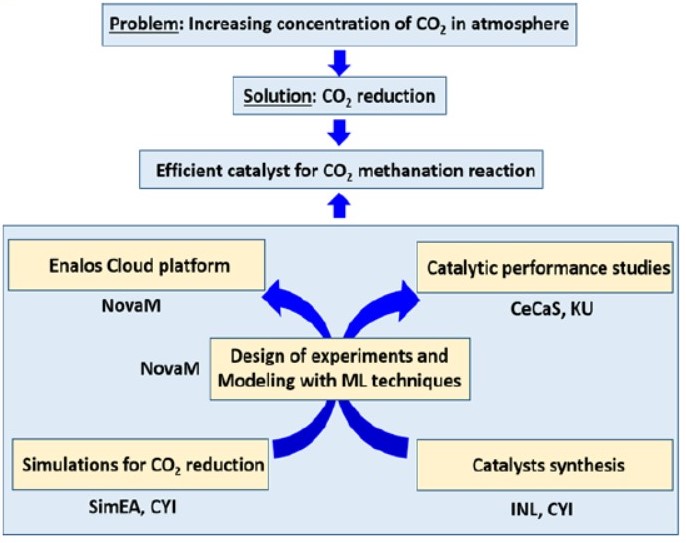

The overall goal of ML-NANOCAT is to realise breakthroughs in catalysis, enabling a new generation of catalytic materials for CO2 reduction, via a synergistic approach that involves multi-scale computational modelling, advanced machine learning (ML) algorithms and tailored design of novel catalysts.

This will be achieved through the following project objectives:

- Obtain structure-property-performance relationships of nanoparticle-based materials for applications in catalysis, focusing on CO2 reduction, via multi-scale computational modelling approaches.

- Synthesise novel catalytic materials that exhibit efficiency and selectivity towards CO2 reduction at a level that goes far beyond the current state of the art.

- Find correlations between molecular characteristics of catalytic materials and their selectivity for specific gases via ML algorithms.

Ultimately, the project will work towards the developement of a software platform for ML-assisted tailored design of catalytic materials, and explore potential patenting of the developed catalytic materials targeting CO2 reduction and, at the same time, build a strong case for transferring the technology developed to catalyst manufacturer companies.

The team

The project brings in the expertise of two research groups at The Cyprus Institute, namely that of Prof. Vangelis Harmandaris (SimEA group) and Dr. George Biskos (INL group), as well as Cypriot company Novamechanics and the Centre for Catalysis and Separations (CeCaS).

The SimEA team has broad experience in developing and applying multi-scale simulations and data-driven computational methods for various materials. The INL group has vast experience in the synthesis of well-defined/engineered NP building blocks for the production of nanomaterials. The expertise of NovaMechanics in the computer-aided modelling and design of materials, as well as in the commercialization of research outputs in materials science, nicely complements the efforts of the research teams. Furthermore, CeCaS (FRO) will provide missing competences in experimental techniques, and access to state-of-the-art facilities.

The Project CODEVELOP‐GT/0322/0093 is funded by the European Union ‐ NextGenerationEU, through the Research and Innovation Foundation